About Us

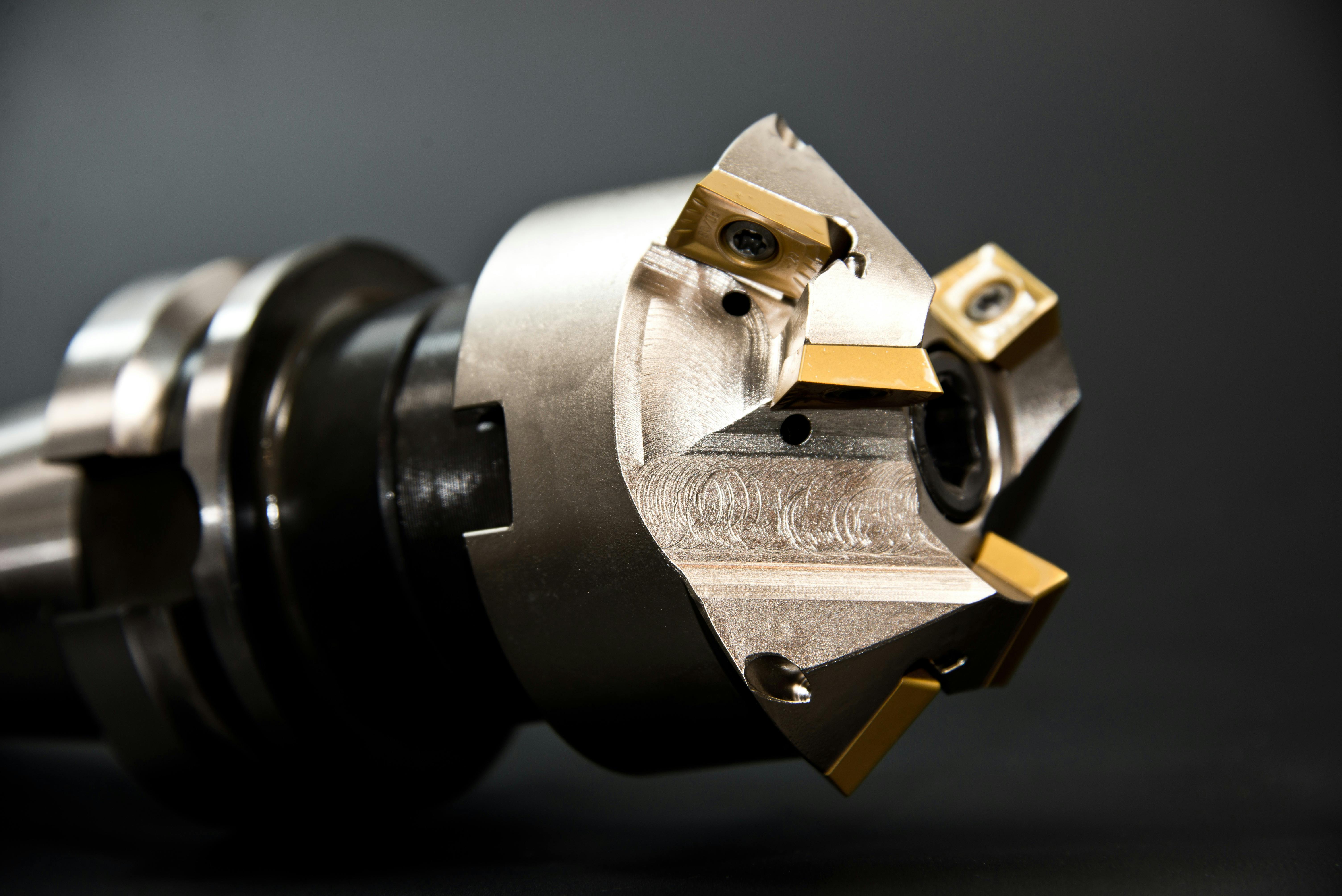

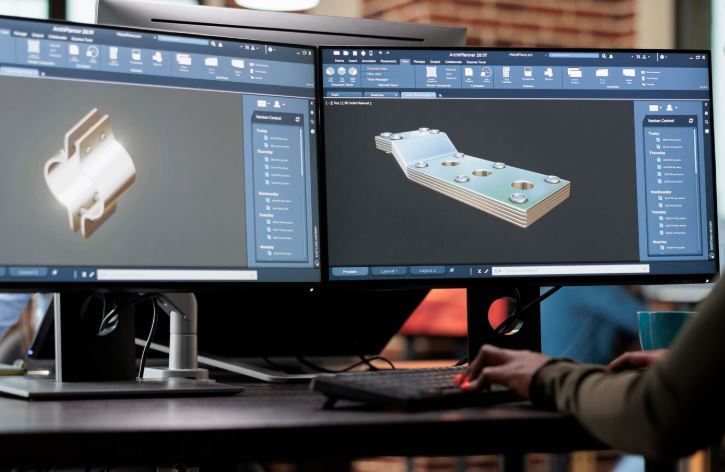

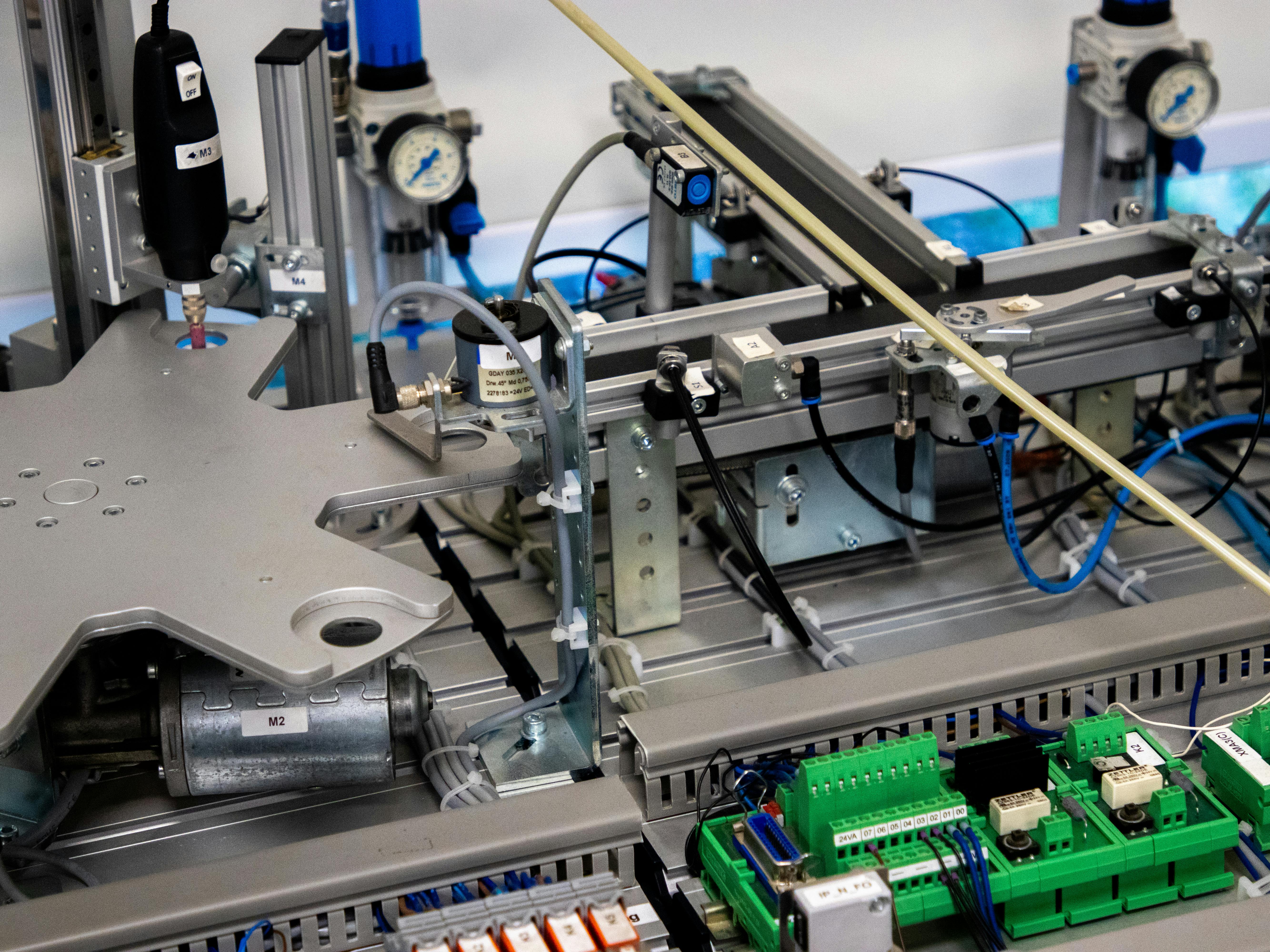

We started our company with one clear goal: to become a reliable partner for organizations seeking top-quality engineering solutions at a competitive price. We specialize in delivering advanced engineering and technical services that improve performance, reliability, and efficiency across multiple industries—including food processing, automotive manufacturing, aerospace, and other specialized sectors. Our capabilities include customized tooling, precision fabrication, automation systems, and fully engineered solutions built to the highest standards.

With years of hands-on experience and strong relationships with trusted suppliers, we combine technical expertise with a genuinely client-focused approach. Every project is shaped around your needs, ensuring solutions that are thoughtfully designed, precisely manufactured, and delivered on time and within budget. Our goal is to provide long-lasting value and support your operations with solutions that truly make a difference.

Through close collaboration with reliable global partners, we maintain the ideal balance of exceptional quality and competitive pricing. This gives our clients access to efficient production options, cost-effective procurement, and high-grade materials—ensuring every solution meets strict performance, safety, and durability requirements.

We believe in open communication, continuous improvement, and building long-term relationships with the companies we work with. We approach every challenge by understanding your goals, anticipating future needs, and supporting you throughout the entire project lifecycle. Our mission is to be a partner you can trust—delivering streamlined, efficient, and future-ready solutions that help your business stay competitive and run at its best.